What is the development trend of industrial machinery and equipment?

The development trend of industrial machinery and equipment includes the following aspects:

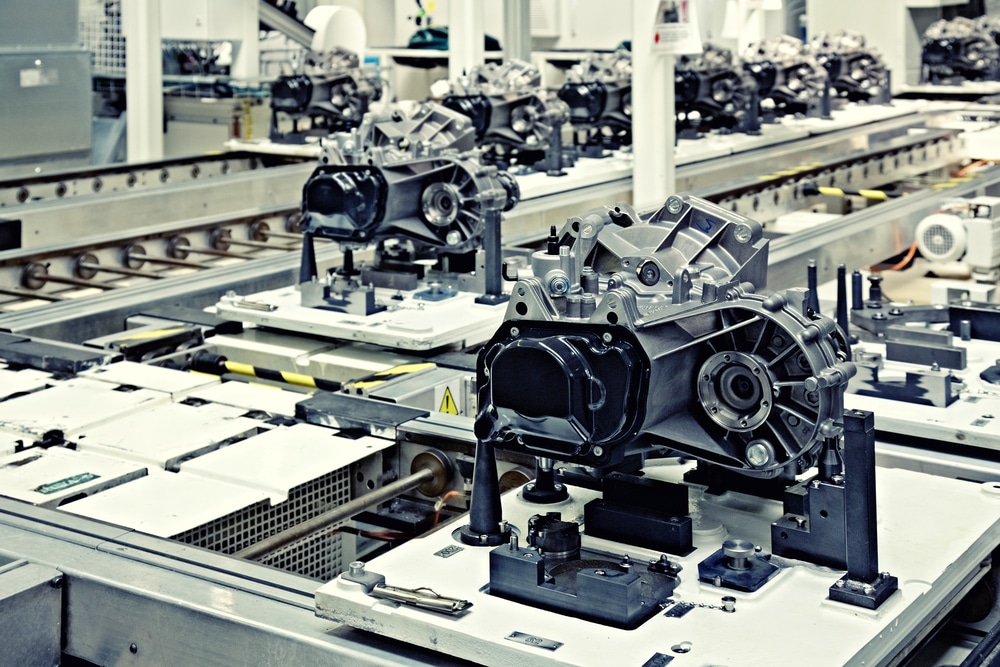

Intelligence and automation: Equipment will have stronger intelligent perception, analysis, reasoning, decision-making, and control capabilities, achieving highly automated production and stronger adaptability to production objects and environments, further optimizing the production process. For example, industrial robots, automated production lines, etc. will be more widely used.

Digital manufacturing: Through digital modeling, virtual simulation and other technologies, comprehensive testing and optimization are carried out before production to reduce costs and time. This helps to improve production efficiency, product quality, and achieve more flexible customized production.

Green and sustainable development: pay more attention to energy efficiency, reduce waste emissions, adopt environmentally friendly materials and designs to reduce the impact on the environment. For example, developing energy-saving equipment, new energy equipment, and promoting the recycling of equipment.

Integration with emerging technologies: Emerging technologies such as 5G, IoT, and artificial intelligence will be deeply integrated into various functional modules of industrial machinery and equipment. This can enable the equipment to adapt to more complex production and management needs, improve efficiency and quality, and ensure the reliability of production activities.

Personalized customization: In order to meet the market's demand for personalized products, mechanical equipment will pay more attention to customized design to adapt to the specific needs of different customers.

Integration of intelligent supply chain and Internet: equipment will be closely connected with other links to achieve more efficient production scheduling, logistics management and supply chain coordination, and improve the overall operational efficiency.

Human robot collaboration: Collaborative robots will be widely used in industrial equipment, closely cooperating with human workers to improve production efficiency, while also emphasizing the design of human-machine safety cooperation.

High end and precision: Continuously improving the manufacturing capabilities of high-end industrial mother machines, precision instruments, key core components, etc., to meet the demands of various industries for high-precision and high-quality products.

Integration and informatization: Deep integration of hardware, software, and application technologies, highly interconnected production equipment and intelligent networks, enhancing the functional complexity and information exchange, self-learning ability of equipment.

Against the backdrop of changes in the global industrial landscape and continuous technological advancements, these development trends in industrial machinery and equipment will drive continuous innovation and upgrading in the industry, bringing new opportunities and challenges to the development of the manufacturing industry.

Please first Loginlater ~