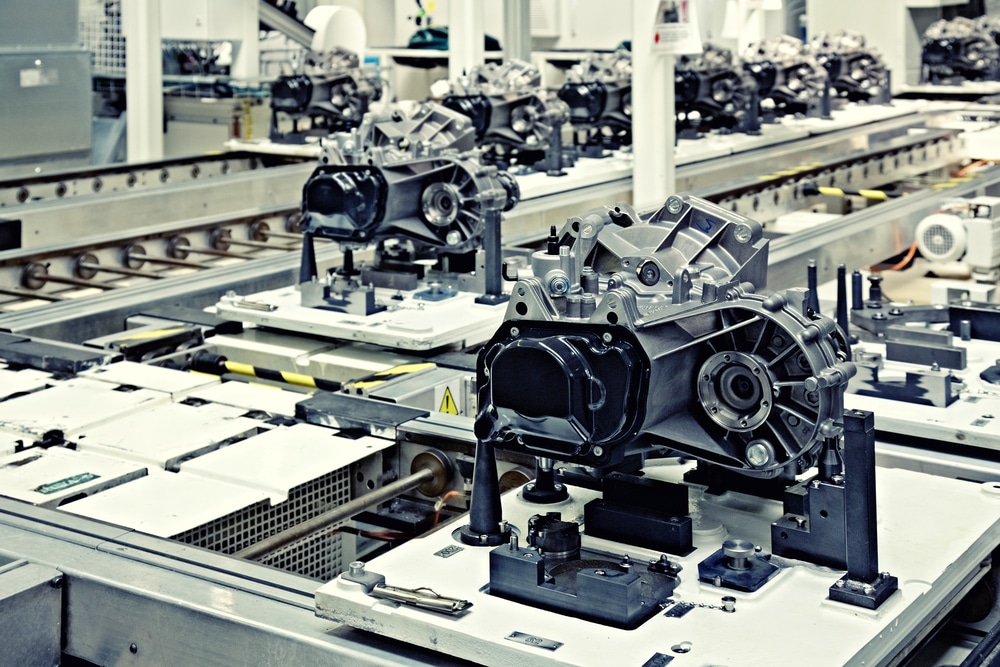

How to evaluate the impact of the development trend of industrial machinery and equipment on enterprises?

Evaluating the impact of the development trend of industrial machinery and equipment on enterprises can be approached from the following aspects:

Production efficiency and cost

Analyze whether the equipment brought about by new trends can improve production speed, reduce production cycles, and thus lower the production cost per unit of product.

For example, automated equipment may reduce manual operations and lower labor costs, but equipment procurement and maintenance costs may increase and require comprehensive evaluation.

Product quality and accuracy

Examine whether mechanical equipment under new trends can improve product quality stability and accuracy, and meet the market's demand for high-quality products.

For example, using more advanced machining tools can improve the accuracy and surface quality of parts.

Market competitiveness

Study the application of new trends by peers in the same industry, compare their own advantages and gaps in technology and products.

If competitors adopt new technological equipment first and enhance their competitiveness, it may pose a threat to the company's market share.

Technical compatibility and upgrade costs

Evaluate the compatibility between existing equipment and new trend equipment, as well as the cost and difficulty of retrofitting or upgrading existing facilities.

For example, can the new digital control system seamlessly integrate with existing production equipment.

Human resource requirements

Considering the changing requirements of new technological equipment for employee skills, is it necessary to retrain or recruit high skilled talents.

Intelligent devices may require employees to possess new skills such as programming and data analysis.

Industry standards and regulations

Pay attention to whether new trends will lead to changes in industry standards and regulations, and whether companies need to adjust to meet compliance requirements.

For example, the increase in environmental requirements may prompt companies to replace more energy-efficient and low emission equipment.

Supply chain and after-sales service

Study the supply chain stability of new equipment and whether the supply of components is sufficient and timely.

Simultaneously evaluate the after-sales service quality and response speed of equipment suppliers.

Return on Investment (ROI)

Predict whether the investment in new equipment can bring sufficient returns within a certain period of time, calculate ROI to determine the feasibility of the investment.

For example, a manufacturing company is considering introducing industrial robots to improve production efficiency, but during the evaluation, it is found that a large-scale transformation of the existing production line is needed, and employees need long training to operate the robots. After considering these factors comprehensively, the decision to invest is made.

Please first Loginlater ~